Hardware as Stagehand

Was making the casing smaller a clear target from the start? Kitano-san?

Yes. At the start of development, Takeda-san gave us the task of making the console a "stagehand", a kind of unobtrusive role behind the scenes.

But the staff members who were thinking up the structure of the casing might have trouble staying motivated if told that what they were working so hard on what was no more than a "stagehand," so it must have been a quite difficult task.

Yes. I could understand what Takeda-san meant, but for those in charge of it, it was a little cheerless and we went about our work solemnly.

Solemnly. (laughs) Being a stagehand comes with its own kind of pride.

Yeah. (laughs) And the Wii U has the GamePad, so we adopted a policy of drastically reducing the characteristics of the main console, causing it to stand out even less. (laughs)

Nonetheless, it is a much more powerful machine than Wii, so you must have devised various solutions for problems related to thermal design and casing size.

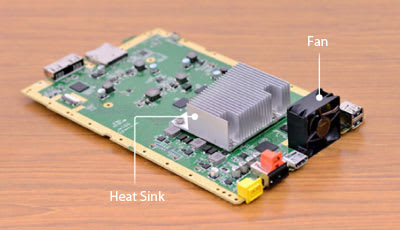

We sure did! We talked about the LSI chips earlier, but a major change was having only one heat source. The Wii had two, so we had to cool both. This is for Wii, and this is the one for Wii U, but to dissipate heat, we had to put in a heat sink15 like this. 15. Heat sink: A metal plate for dissipating heat. A type of radiator or radiator plate. They are often made in a pin-holder shape with projections called fins.

Compared with the Wii, the Wii U has about three times the amount of heat, so we really had to wrack our brains. We considered solutions such as making the fan bigger and raising the number of fan revolutions. We conducted heat tests for prototypes a number of times and optimized placement of the air holes.

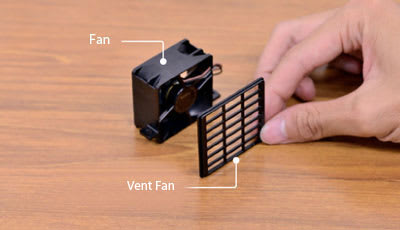

Another small detail is the vent cover in the back of the fan. We had to put a lot of work into improving efficiency, making it thinner and slanting the inside so that the air could escape more smoothly.

I see. This is like an article breaking down and reporting on a new product right after release! (laughs) It's not like you have a single magical idea. Rather, you go to a lot of trouble, building up a number of improvements to make it relatively compact despite the heat generated.

Right. In regards to heat test, the number went over 2,000.

Huh? Two thousand?! I never imagined it would be so many!

One test takes about one hour, so we put a ton of time into testing it on the way to its current form.

We also do fan-noise testing, so it takes a lot of time.

Yeah. If you increase the number of fan revolutions, it makes more noise, so we checked to see how much noise was acceptable while playing games. Adjusting the number of fan revolutions changes not only the noise but the heat level. Our goal was to see how efficiently we could dissipate the heat, so we applied ourselves to one thing after the next.

I would guess it's most advantageous to place the core's heat source next to the fan, right? It's important that a lot of air pass through the heat sink, isn't it?

Yes. The basic structure is that the heat sink is over the MCM and the fan is directly behind it. It is advantageous for heat dissipation to have more air on the heat sink. However, we learned through testing that you have to dissipate the heat while securing a certain amount of airways or it isn't efficient.

But in this position, the drive is obstructing the air route. This is purely my own personal interest…

Yes, so in the product...

Oh! It's clear! Cool!

(laughs)

You've got to sell this to me! (laughs)

(laughs)

Basically, this is a vent, and this is an inlet.

Oh, so that's how the air flows. The whole thing, including this structure, allows the air to flow efficiently and dissipate heat.

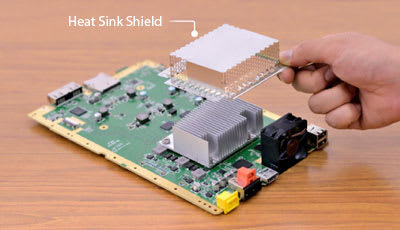

The main intake is on the side, but to support airflow there are also openings on the top and bottom. And, uh…sorry to be crowing about all this stuff (laughs), but see this part with all the fine holes in it? This is called a heat sink shield. It suppresses the electric waves from the board.

The heat has to dissipate, but you have to trap the electric waves inside. The area of the holes is really big, but the mesh is comparatively fine.

Yeah. There are especially a lot of round holes. Machining that part was quite a chore.

(closely holding the transparent casing) Seeing it like this, I can tell there's a lot packed in here!

Yes there is! (laughs)